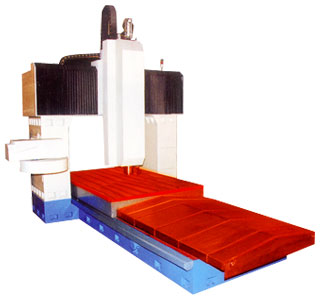

TH2030 bare machine is integrally formed by precision casting through resin sand type high-strength cast irons, with reasonable ribbon structure, good rigidity, totally aged treatment and strong stability. The lathe adopts a gantry structure and the worktable is movable. The main axle-box part adopts a dual-cylinder balance mechanism so as to ensure the motion stability of the main axle-box. The crossbeam adopts a large-dimension section design so as to reinforce the bending stiffness and torsional stiffness. Rolling guideways are assembled on the upper surface and side surfaces of the crossbeam so as to reinforce the anti-rolling capability of the main axle-box. Hard-rail quenching process and sizing process are applied to Z axis, thus being beneficial to improving the cutting stability and wearability. The guideway adopts imported 65# overloaded pre-tightened guideway. The screw rod adopts imported R80-010 C5-grade grinding screw rod, with two ends being fixed and pre-stretched. All bearings are imported P5-grade bearings in pair. The mainshaft is BT50 straightly-connected precision mainshaft produced in Taiwan, with the maximum rotating speed of 6000r/min. Stainless steel protective shields are provided before and after Y axis, X axis adopts a flexible organ cover. The flexible organ cover is also arranged below the handpiece. Furthermore, automatic lubricating systems are provided, and tool storage mounting surfaces are reserved. The appearance of bare machine shall be painted with required colors. The bare machine does not contain any electrical apparatuses.

| Item | Requirement (unit) or specification | Remarks |

| Dimensions of worktop | 1940X3000 | |

| Width of gantry | 2310 | |

| Distance from end surface of mainshaft to worktop | 120-1120 | |

| Vertical stroke (Z) of mainshaft | 1000 | |

| Lateral stroke (X) of worktable | 2000 | |

| Longitudinal stroke (Y) of worktable | 3000 | |

| X-axis linear guideway | HGW65HA3RH | Hiwin |

| Y-axis linear guideway | HGW65HA4RH | Hiwin |

| Z-axis hard guideway | Sliding part adopts wearable films | Imported |

| X-axis and Z-axis ball screw rods | R65-010-0.018C5-grade | Hiwin |

| Y-axis ball screw rod | R80-010-0.018 C5-grade | Hiwin |

| Type and rotating speed of mainshaft | BT50、6000R/min | Volis |

| Three-axis bearing | Angle-contacted P5-level bearings in pair | Germany |

| Connecting forms of three-axis and mainshaft | directly-connected three-axis and mainshaft connected by synchronous belt | |

| Torque of Recommended three-axis motor X/Y/Z | 32Nm 45Nm 40Nm | |

| Recommended power of mainshaft | 15-18.5KW | |

| Quantity-dimension*spacing of T-shaped trough of worktable | 9-22X225 | |

| Planeness of worktable | +0.05 | |

| Maximum loading capacity of worktable | 3500(Kg) | |

| Verticality of Z axis on XY axis | 0.05 | |

| Planeness of Z axis when moving | 0.08 | |

| Positioning precision | 0.05 | |

| Net weight of bare machine | 28000Kg | |

| Outline dimension | 7400X3410X4600 |